That one’s easy. What we do is to rescue plastic and other recyclable waste that’s been dumped into the world’s oceans and waterways (or is on the way there) and then turn it into high-performance textiles and polymers. Pretty straightforward.

That one’s a little more involved, but it’s worth getting into because we believe that a large part of building a sustainable economy is about knowing where the things you buy come from. That’s why it’s so important to us that our raw materials are fully traceable. We know exactly where our materials come from – the country, the community, sometimes the very beach – because we were there when they were picked up. And that means that YOU can know exactly where your products come from too.

Before we gather a single piece of plastic, we start by identifying a coastline in need. Unfortunately, in today’s world, there’s no shortage of communities that need help cleaning and maintaining their coasts. We don’t just parachute in and start operating, but first gain community support for local clean ups and recycling efforts, because a key component of ridding our oceans of plastic is to divert it before it even gets there. Then we start building infrastructure. That can be as simple as recycling drop-off points, and as sophisticated as a full sorting and shredding facility. In short, we plan, build, and operate waste management services in places where there weren’t any. That means we’re often teaching communities how to use those services, because they’ve never had them before.

After we get the community on board and our systems in place, we can finally start collecting. Our collection process is broken into three distinct streams: self-serve recycling stations, direct pick up from businesses, and coastal clean ups. The recycling stations and the commercial collections are serviced directly by our employees, but clean ups are often a communal affair. We engage school groups, non-profits, friends, family members, and anyone else who’s interested in clean oceans to comb beaches and coastlines for wayward bits of waste. To manufacture BIONIC products, we need PET (plastic soda bottles, etc) and HDPE (milk jugs and the like), but we don’t limit our collecting to the things that we can personally use. We realized early on that this was an all or nothing process; we couldn’t just take the stuff we wanted and leave the rest behind. So anything recyclable – all plastics, glass, terapaks, etc – is collected, sorted, and sent somewhere it can be used.

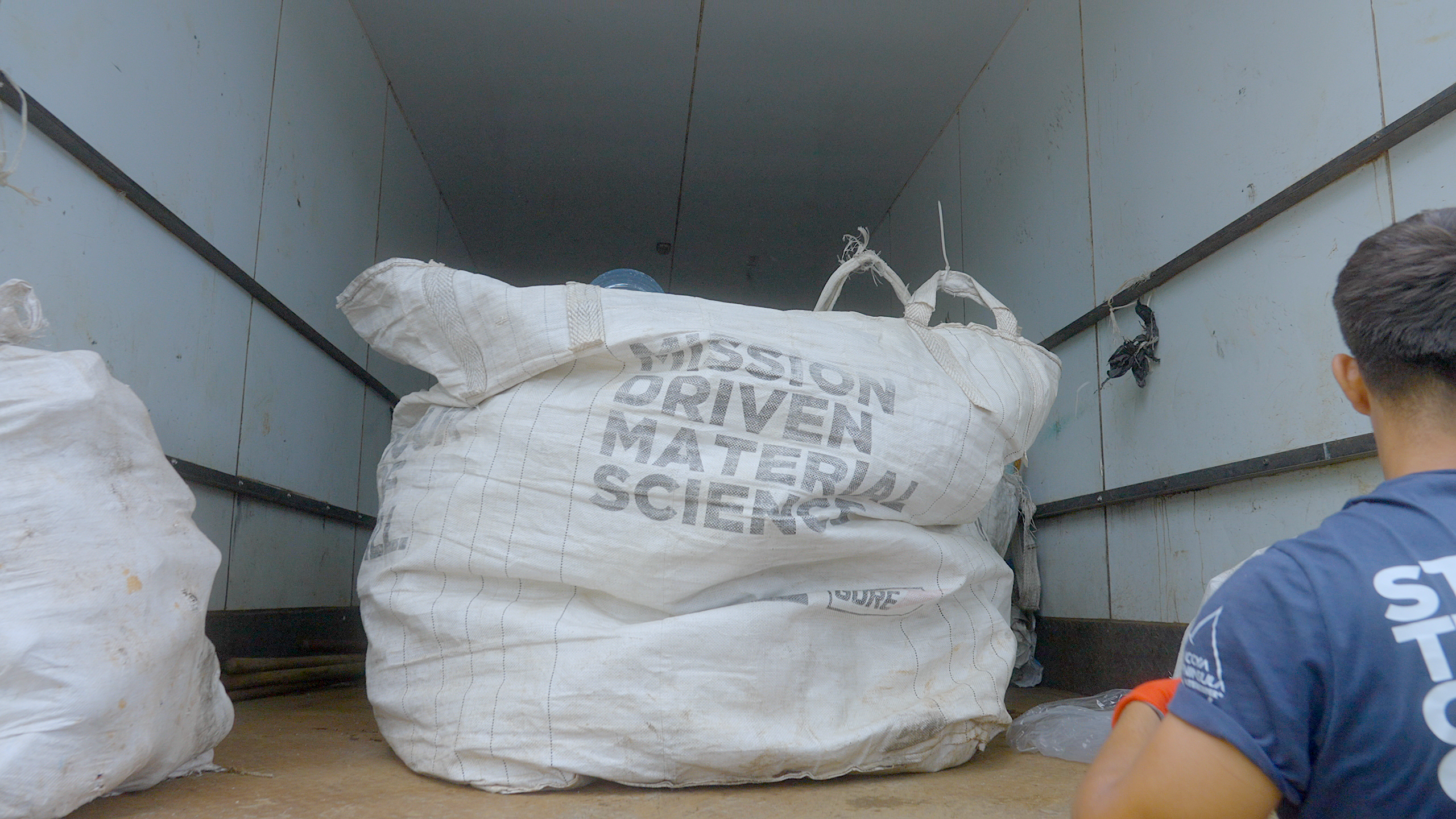

One of the most frequently overlooked components of our supply chain is transport. We’re collecting in some very remote corners of the world, and the recovered plastics need to eventually make it to a processing facility to realize their full potential. When it’s a far-flung beach clean up, that might mean using boats and 4-wheelers, but day to day, we run a well-oiled network of local trucking routes. We are the recycling truck, from pick-up to processing.

This is the dirty work, everything that happens after we take the plastic out of the environment and before it can become something new. During the processing stage, we’re getting reclaimed plastics ready for their new life. That means sorting by material and color, compacting, grinding, and warehousing, all in a regional facility near where the materials were first collected. Once we’ve got a load of shredded plastic flake, we ship it onwards to the next step: pelletizing.

The moment that the old plastic becomes something new. The ground flakes are cleaned of contaminants like labeling and sand, then melted together and passed through a spineret, which restructures the plastic and extrudes (a great word for “spits out like a pasta maker”) long threads of polymer, which are cut into little pellets. These pellets are the base material of everything we make.

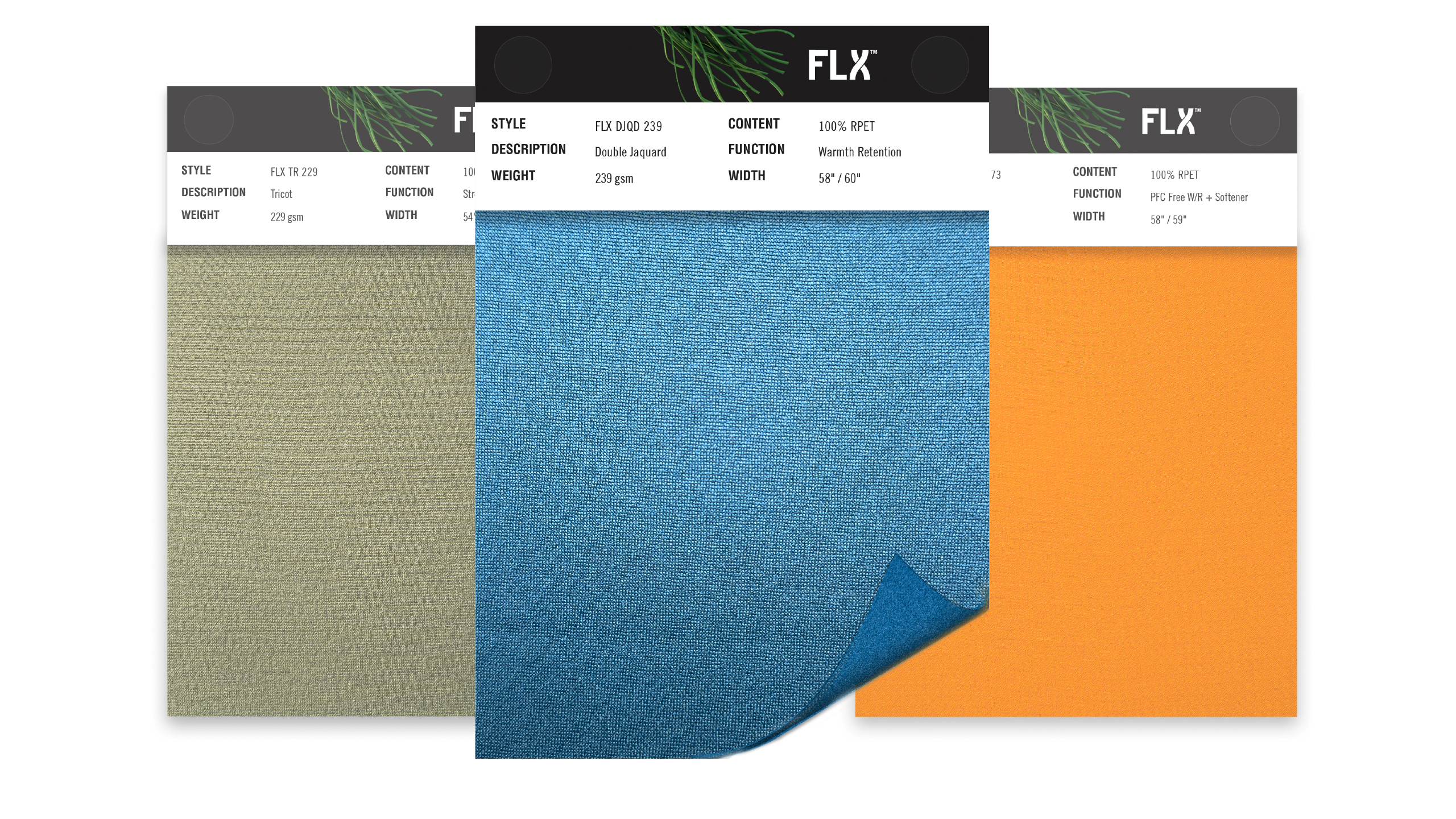

When the end goal is a textile, we first need to spin the yarn. In one of the many partner mills we employ around the world, our marine plastic pellets are re-melted and extruded (there’s that word again) into long filaments. These filaments are spun into three types of yarn, each of which can be customized to produce a nearly infinite variety of textiles. What makes one different from another is what we blend with our reclaimed plastics. Our FLX yarn is made with rescued marine plastic; our DPX yarn blends the recycled plastic with other natural or synthetic fibers for a softer texture; and last but certainly not least, our HLX yarn uses a three-layer construction that blends even more fibers into the complete performance package, while still keeping a recycled heart. Once you have the yarn, the sky’s the limit, and we can weave nearly any textile you can dream up.

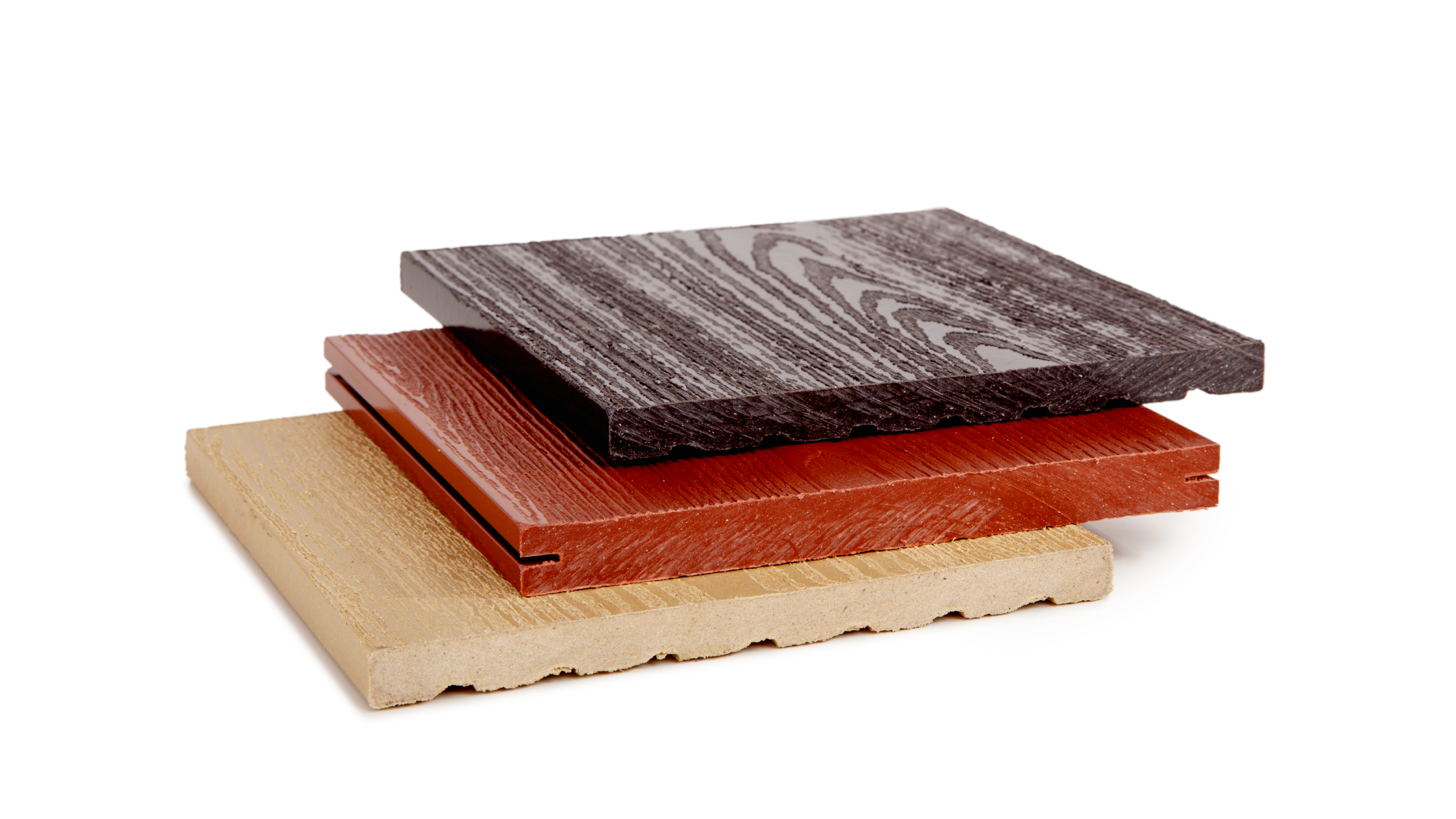

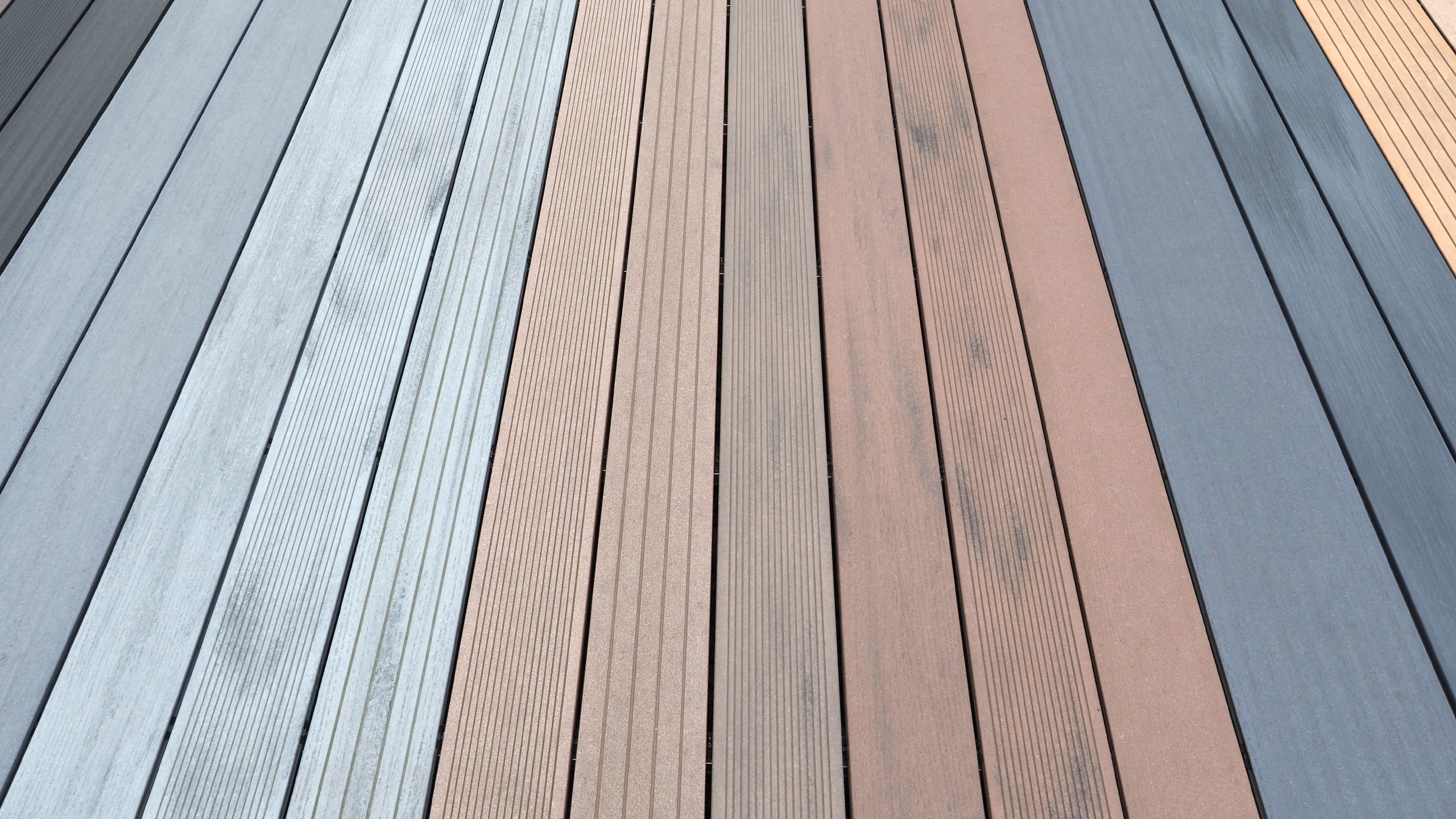

Not all of our raw pellets get made into filaments for yarn. Some are used to create customized polymers by re-melting and mixing them with new colors and compounds, giving them certain unique properties. Polymers like these are the building blocks for most of the plastic items you see in the world around you, objects that are 3D-printed, injection molded, thermo molded, or otherwise fabricated.

Finally… the best part. You’ve got your materials, now make something cool. Our textiles and polymers are used for a stunning variety of products. The fabrics have walked runways around the world, climbed the Alps, and then snowboarded down the other side. Our polymers are in the legs of lifeguard chairs, the frames of your glasses, and the case on your phone. The end product all depends on what we’ve mixed with the most important component – recovered marine plastic. So whether you decide to make car components, engineered lumber, or a jean jacket, you know that you’re also contributing to cleaner coastlines and oceans.